Precision Machining Solutions

OPEL provides total machining solutions including sourcing of raw materials such as castings, forgings and fabrication for customers across industries such as construction equipment, earth moving machinery, automobile, defence, marine, infrastructure, transmission, compressor, tractor textiles machinery, wind energy, railway, special valves, mineral processing and petrochemical.

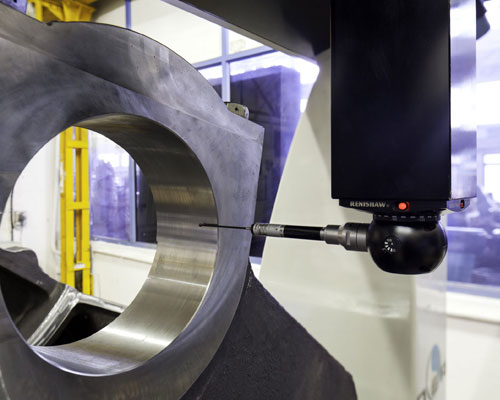

Machining Facility

OPEL provide end-to-end manufacturing solutions including sourcing of raw material within shorter lead time. Following our company ethos “A Commitment to Excellence” we have been consistently achieving:

- Shorter development cycle, for our clients.

- DOL supply status for regularly supplied products to leading OEMs.

- We are considered as the Preferred partner by all our existing customers.

- Quick ramp-up and up-gradation of facility.

| S.No | Machine Description | Table Size in mm | Max load in kg | ||

| Minimum | Maximum | ||||

| 01 | Horizontal Boring Machine | 1600 X 1800 | 3000 X 2000 | 30000 | |

| 02 | Horizontal Machining Centers | 400 X 400 | 1000 X 1000 | 20000 | |

| 03 | Vertical Machining Center | 750 X 450 | 3200 X 2070 | 11500 | |

| 04 | Horizontal Turning Center | chuck 250 | chuck 600 | 8000 | |

| 05 | Vertical Turning Center | chuck 305 | chuck 3000 | 18000 | |

| 06 | Conventional Lathe, Drilling and Boring Machines | ||||

Quality

OPEL follows stringent quality control measures at all stages of production to ensure flawless end product. Sourcing raw materials from authentic vendors and overseeing all operations with experienced committed professionals, we are able to deliver quality products consistently as committed.

- OPEL use world-class, state-of-the-art testing and validation facilities

- CMM- DEA Hexagon-Table size-1200*3000*1000 & 700*1000*2700

- OPEL has full fledged gauges/Instruments room.

Quality Policy

- OPEL is committed to, Exceed “customer expectations” through continuous improvement in quality and timely deliveries

- Encourage self-improvement & dedication of all employees through effective training & empowering with authority to discharge their responsibility.

Design & Engineering

OPEL has dedicated design & engineering team, extensive In-house manufacturing facilities.

- Focused team for process development

- In-house fixture manufacturing

- Project teams for product development

- Separate tool room & CAD center